The rotating of the blade is based on the natural frequency and mode shapes. I am looking for good authortextbook recommendation on the following.

Software For The Design Of Pumps

Centrifugal Pump Impeller Design.

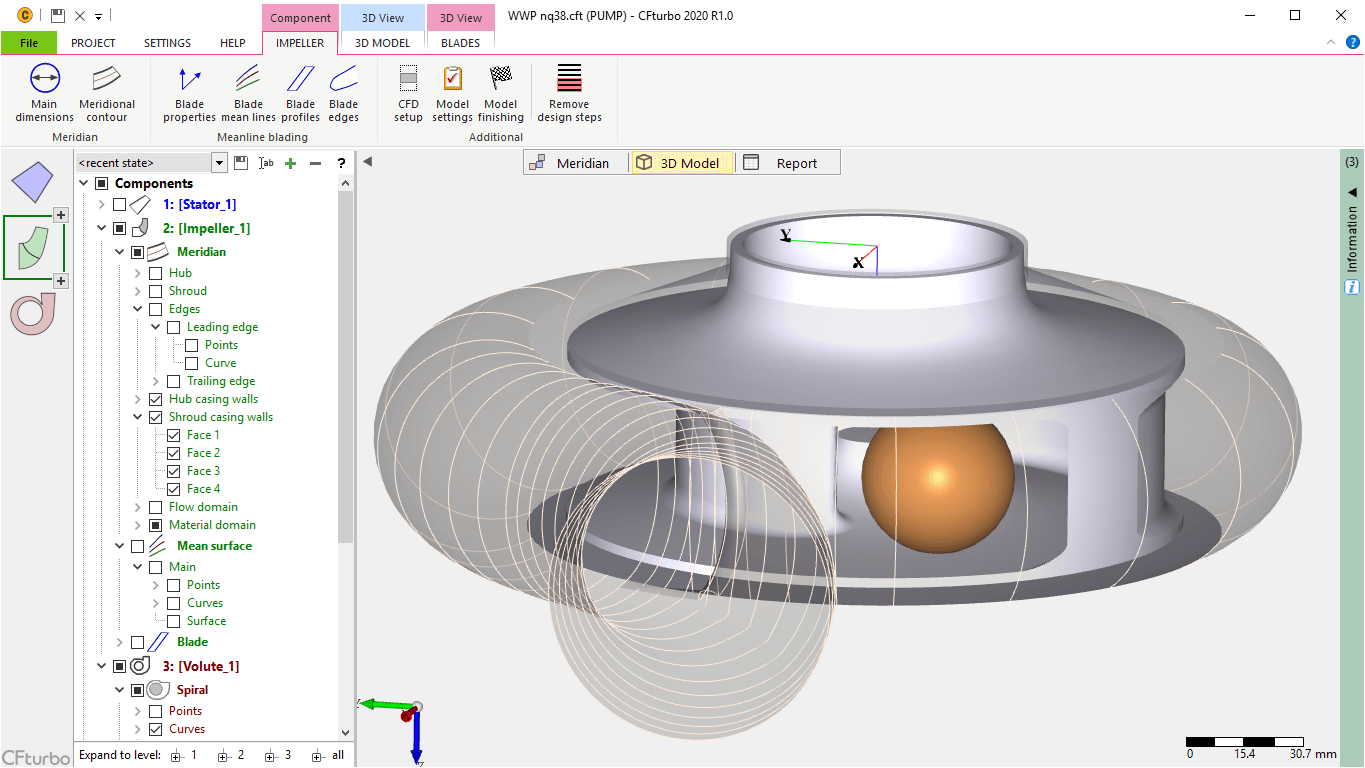

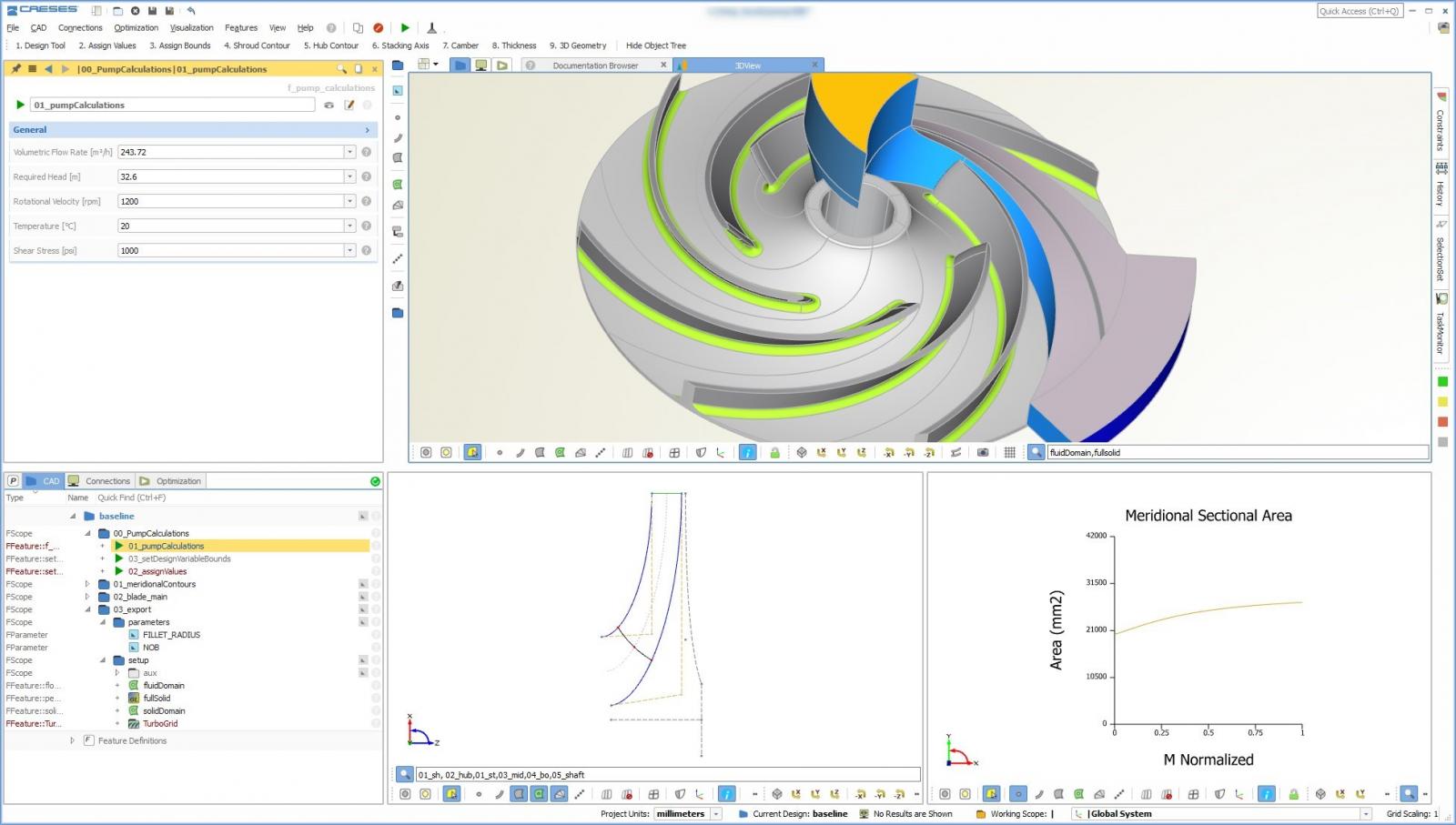

. CFD methodology is used for analysis purpose and K- turbulence model is used as turbulence model. CENTRIFUGAL PUMP DESIGN AND PERFORMANCE OPTIMIZATION USING. CAE Software for Axial and Radial Pumps.

Outline Introduction Pump Theory Design of impeller and volute Loss models Code implementation and CFD analysis Results Discussion. Pipe Flow Analysis Software. MTU large Diesel engines for compressor and turbine optimization.

Alternatively the surface model of a centrifugal pump can be created in an open-source software like for example Salome FreeCAD or Open Cascade. BladeGen in ANSYS CFX 120 or later. 1 shows the generation of blade profile.

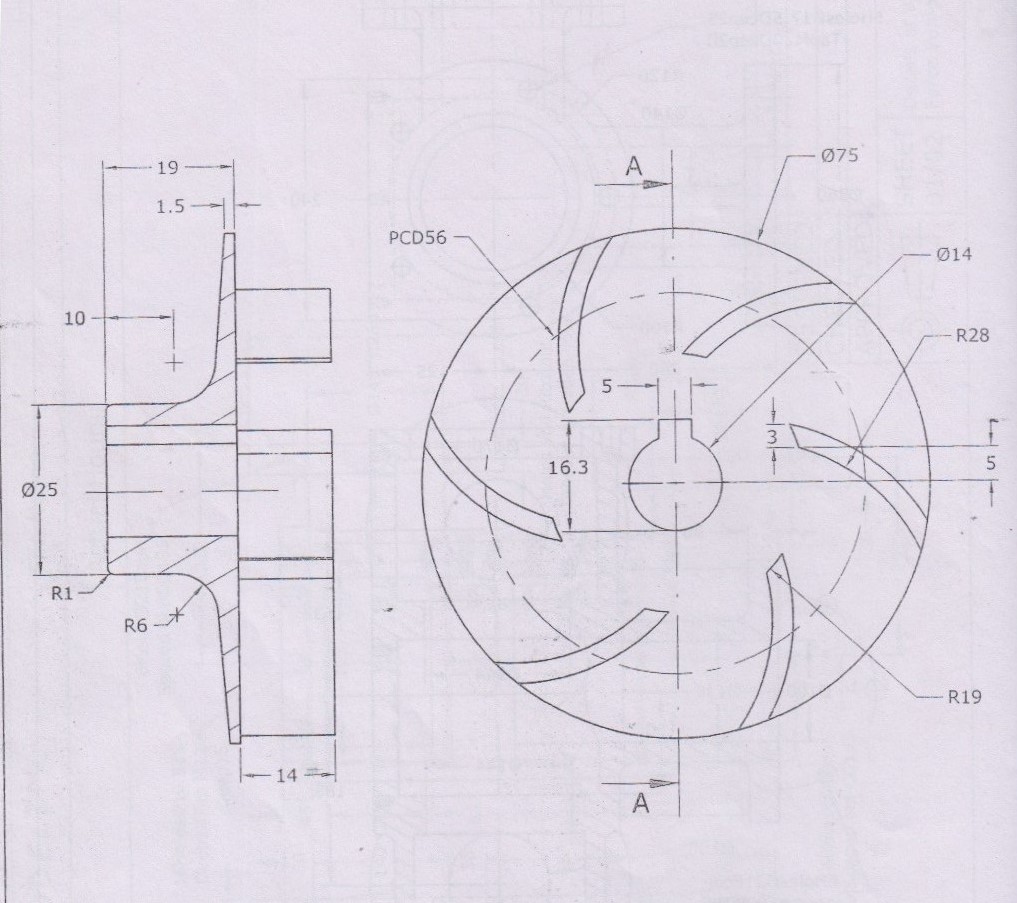

The objective of this paper is to be design the impeller for a centrifugal caustic slurry pump to increase its power and efficiency and showing the advantage of designing parameters six blade turbine design changes from impeller comparing with the old material of a TURBINE. The casings of centrifugal-pumps are usually. After replacing the impeller a new pump impeller was optimally designed.

Given the high performance of the baseline impeller the. To anyone who can help. Centrifugal Pump Preliminary Design Software.

It is proposed to design a blower with composite material analyze its strength and deformation using FEM software. The impeller chosen for the study was a single- entry impeller with radial vanes. The double-discharge volute casing is a structural constraint and is maintained for its shape.

Geometric characteristics of impeller in the pumps. From a simple pump selection in a buildings water supply plumbing system to the more complex evaluation of the operation of pumping stations with centrifugal pumps connected in series or in parallel in water conveying pipeline systems BOMBAS PUMPS desktop version puts the easiest way of performing. The numerically sim-ulation results show that the hydraulic performance of the newly designed impeller of the mixed-flow pump were obvi-ously improved and the engineering requirements of the were satisfied.

Fluid enters the rapidly rotating impeller along its axis and is cast out by centrifugal force along its circumference through the impellers vane tips. The redesign effort was geared towards meeting the design volute exit pressure while reducing the power required to operate the fan. The vibration is mainly caused by blade exit angle.

Model both centrifugal and positive displacement pumps in piping. Patel et al2 2014 had undergone design and analysis of centrifugal pump impeller. The complex internal flows in Centrifugal pump impellers can be well predicted through ANSYS-CFX.

Solid modeling software CATIA V5 R18. There are free academic versions of the CAESES pro edition for students and. 103Internal compressor casing diameters can be up to 4000 mm for horizontally split compressors and 2600 mm for barrel designsInlet flows for centrifugal compressors can reach 300000 m 3 h.

The numerical solution of the discredited three-dimensional incompressible Navier- Stokes equations over an unstructured grid is accomplished with an ANSYS-CFX. ERKAN AYDER 4 DECEMBER 2018. Initially two concentric circles representing the outer and inner diameter of.

The design procedure involves the computation of required water path by using the laws of fluid motion. A method is presented for redesigning a centrifugal impeller and its inlet duct. Application of internal or user-defined approximation functions to define impeller parameters.

Calculation of the impeller main dimensions. With the best impeller has better hydraulic performance than the original centrifugal pump. It is most common pump used in industries and domestic application.

In this paper analysis of centrifugal pump impeller design is carried out using ANSYS-CFX. A meanline approach is used to design centrifugal pumps and mixed-flow pumps with single and multiple stages. Conventional design method is used for determining values of different parameters.

A centrifugal pump is a mechanical device designed to move a fluid by means of the transfer of rotational energy from one or more driven rotors called impellers. Design steps for radial and mixed-flow impellers. Centrifugal pump impeller design21.

In the context of turbocharger design CAESES is used by eg. Pump is singe stage single suction horizontal cantilevered centrifugal dredging pumpTobee designs and researches this new type dredging pump by making full use of advanced CAD software aiming to dredging river lake and seal which is in great need to dredge in the worldThe use of this dredge pump has remarkable comprehensive economic benefits and can meet. Ments was found out.

M Issa Design and Analysis of Centrifugal Pump Impeller using ANSYS FLUENT International Journal of Science Engineering and Technology Research IJSETR vol. Shardul Sunil Kulkarni6 2014 explained about. This free demo of AFT Fathom allows engineers to go beyond hand calculations and spreadsheets to better calculate system pressures simulate pump performance and analyze hydraulic behavior.

In order to. Meshing in ANSYS CFX 120 or later. Rgeiss Mechanical OP 18 Jan 13 1740.

Vista CPD in ANSYS CFX 120 or later. The analysis of centrifugal pump impeller design is carried out using ANSYS-CFX. Centrifugal pump performance mainly depends upon blade exit angle.

Hub diameter suction diameter outlet width impeller diameter. Get clear results to solve your pump and system problems. The centrifugal pump Preliminary Design procedure is used to create thousands of machine flow path designs from scratch within seconds from a set of boundary conditions geometrical parameters and constraints.

Introduction A centrifugal pump is one kind of general machinery 1 which is widely and fully utilized in the industrial and agricultural fields 2 such as. A large 1750 mm diameter impeller is shown in Fig. PUMPAL is used to design the stage analyze performance refine the parameters with data reduction and model the machine according to several performance models.

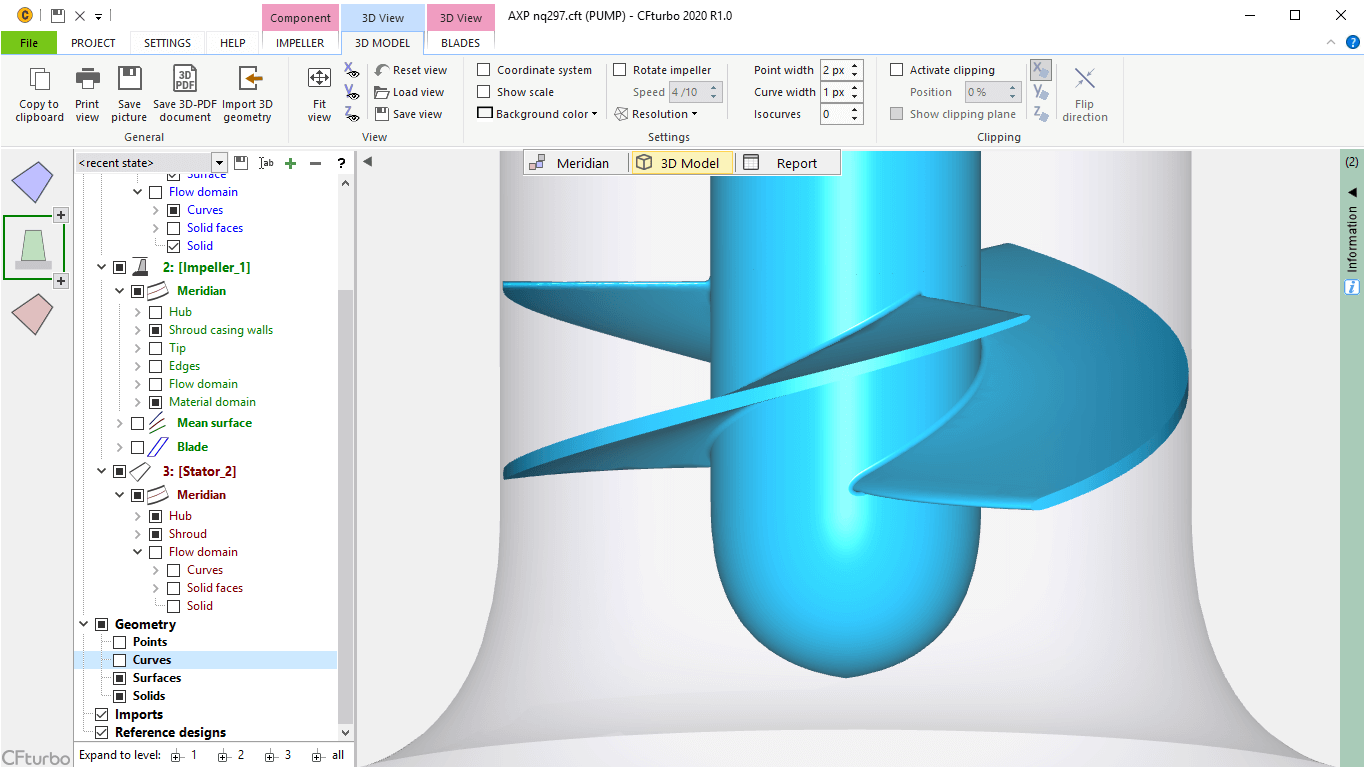

AxSTREAM can design centrifugal pumps with or without outlet volutes diffusers. The CAD model of the impeller was done using NX CAD software. Or engineers can use a special dedicated software for turbomachinery design like for example CFturbo Concepts NREC or TURBOdesign Suite and create the CAD model and export STL surface.

Applicable to pumps fans compressors and turbines. The pump design and performance optimization software has been implemented on Java 18. An investigation in to usage of new materials is required.

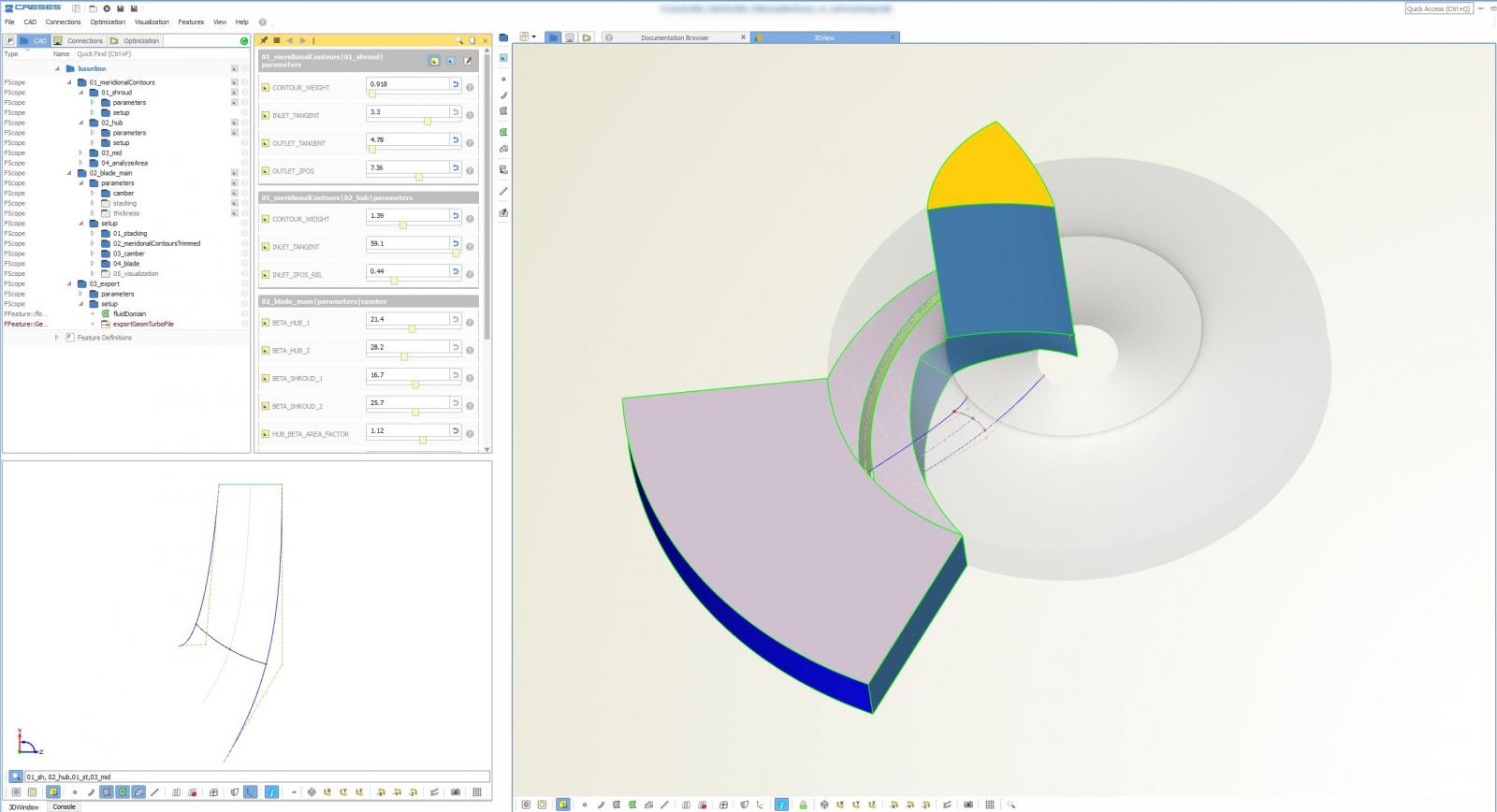

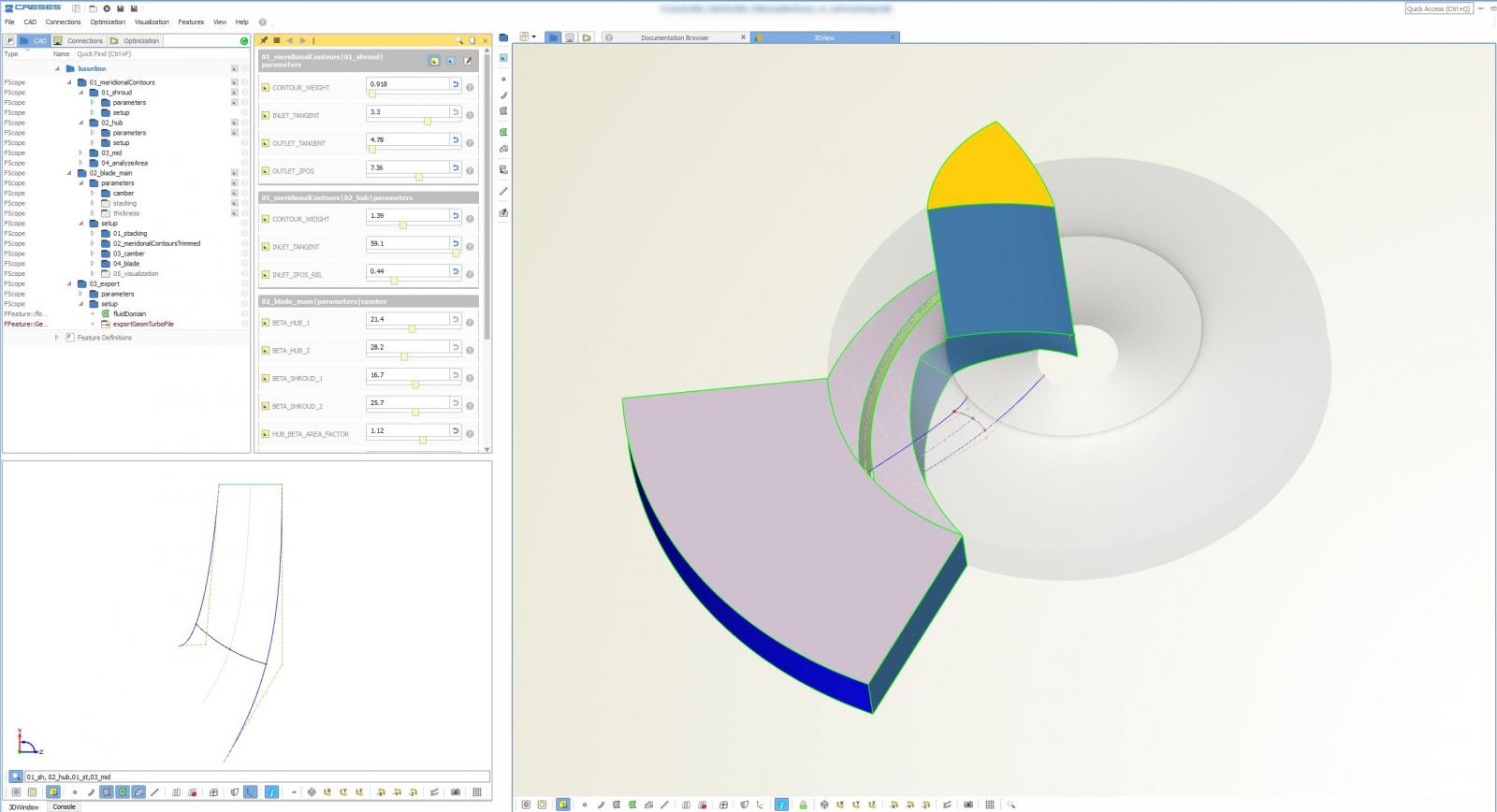

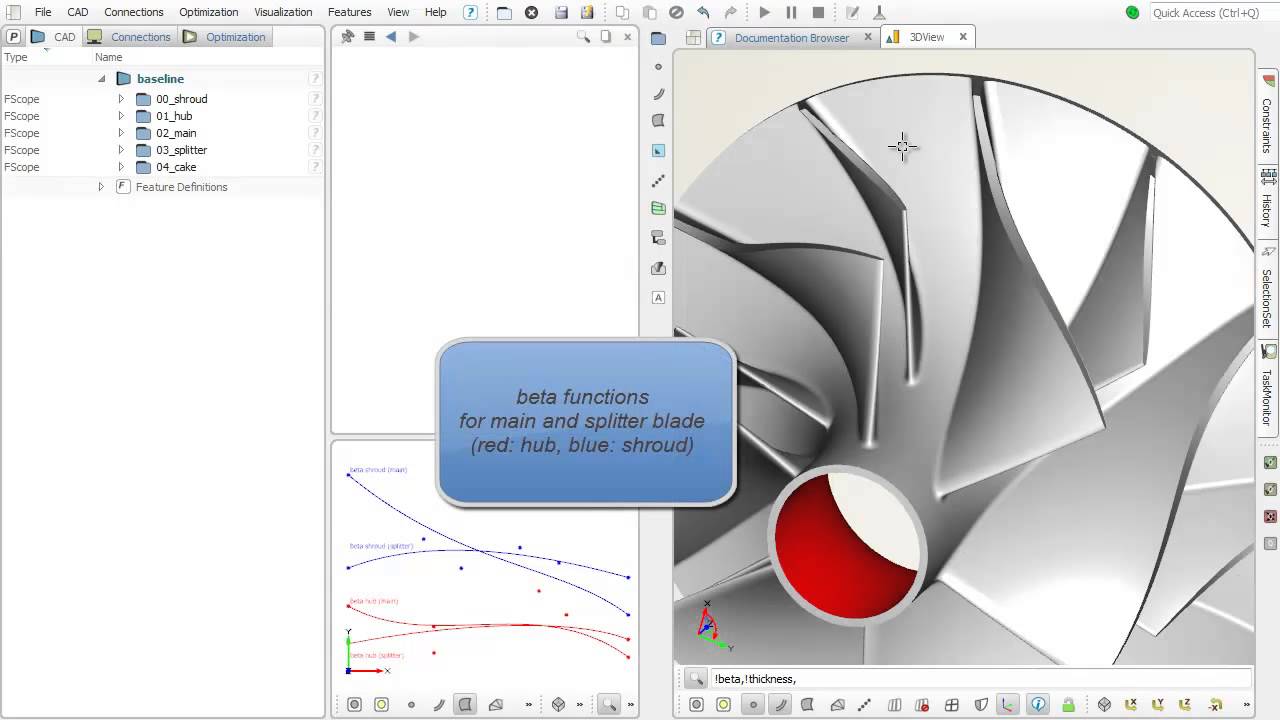

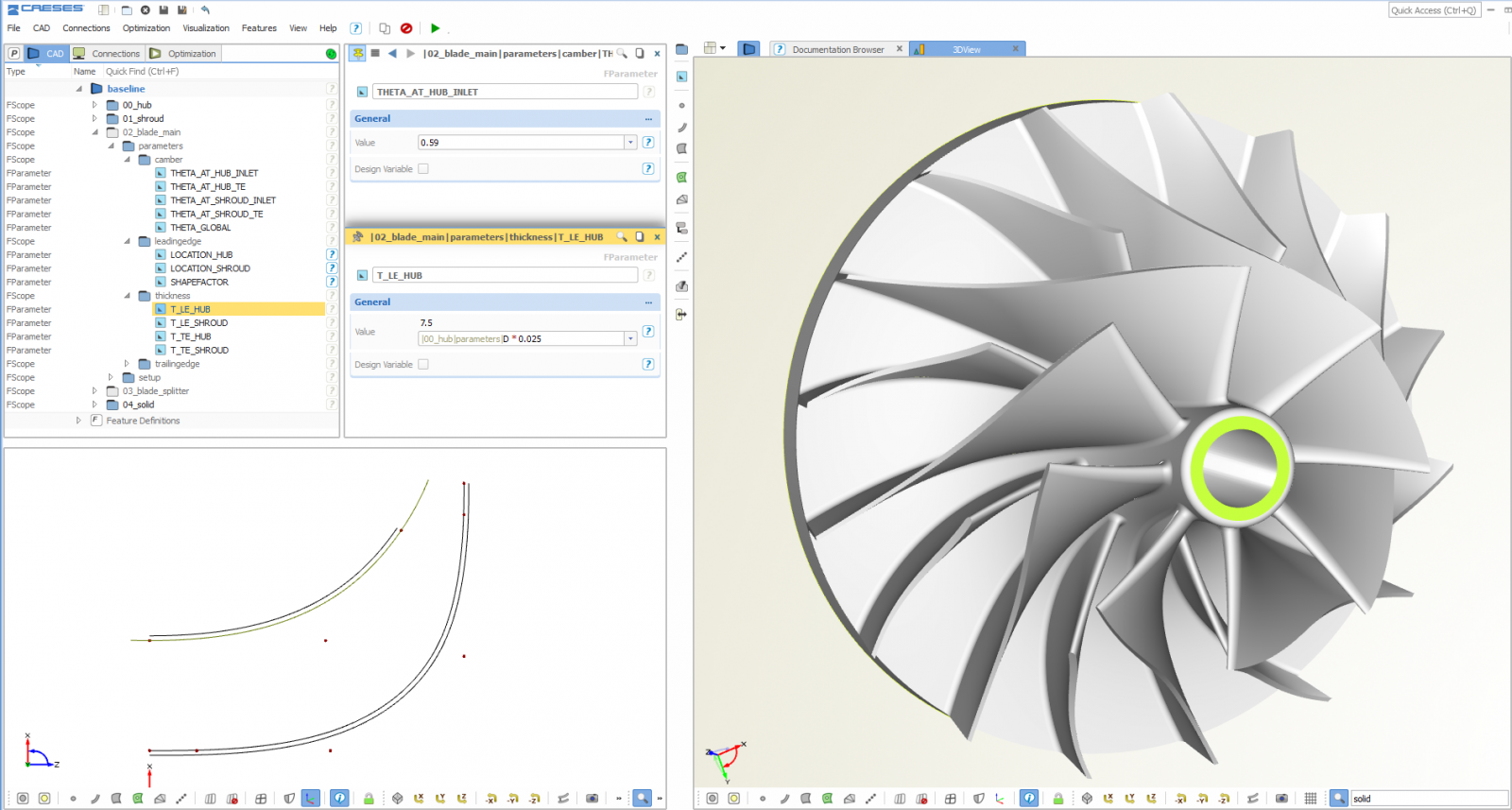

Centrifugal Pumps Selection Software. The LNG compressors can be extremely large with centrifugal impeller diameters in the range of 13002000 mm. CAESES is used by several major pump makers KSB Ebara Grundfos DMW mostly in the context of impeller and volutecasing optimization.

Free Impeller And Pump Design Software Miscellaneous Caeses Forum

Cfturbo Demo On Centrifugal Pump Design And Simulation Youtube

Centrifugal Pump Software Ciclo Software

Centrifugal Impeller Design Youtube

Software For The Design Of Pumps

Free Impeller And Pump Design Software Miscellaneous Caeses Forum

Design Of Impeller For Centrifugal Pump Grabcad Tutorials

Free Impeller And Pump Design Software Miscellaneous Caeses Forum

0 comments

Post a Comment